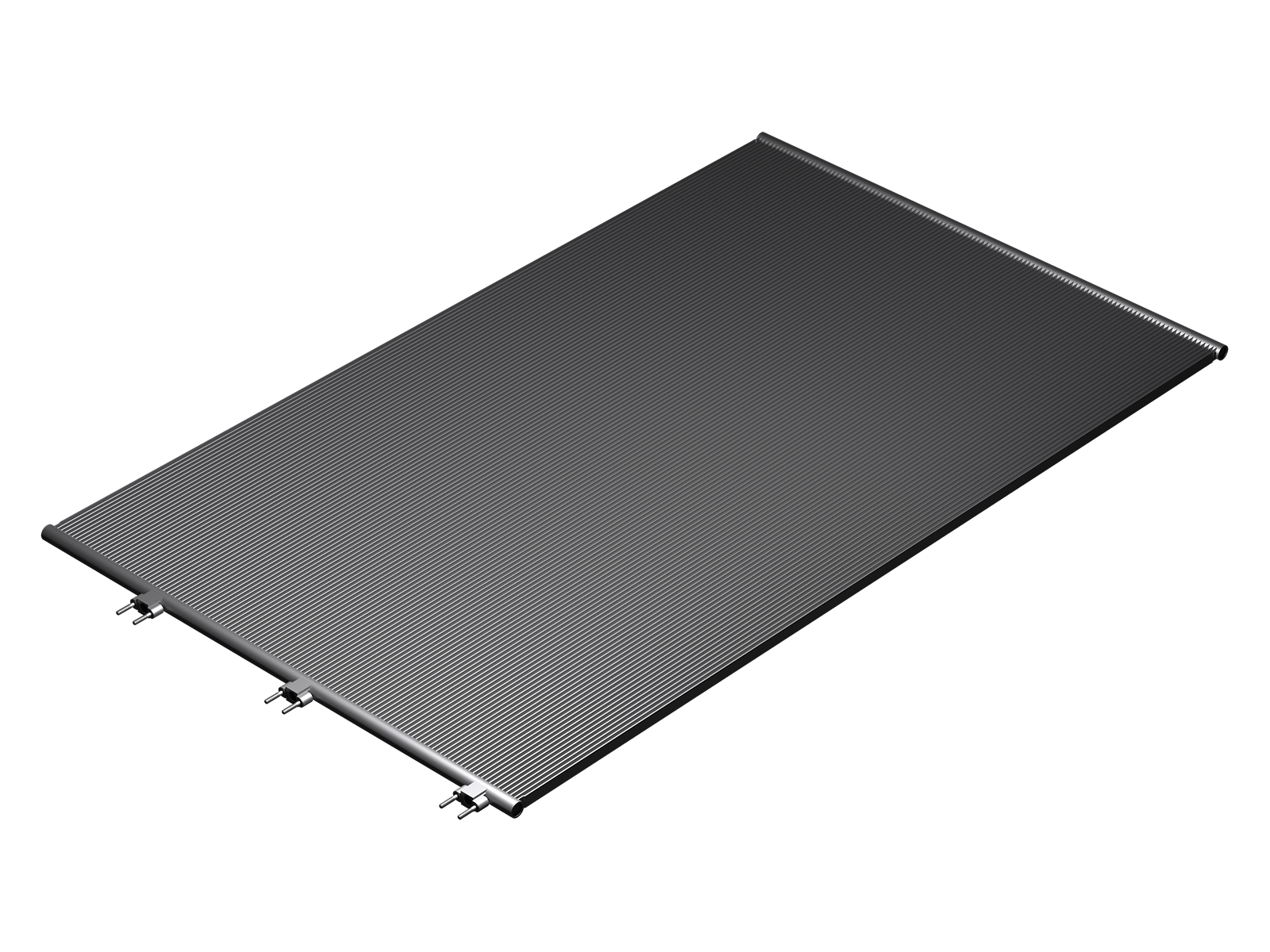

Microchannel heat exchangers (MCHE) have revolutionized air conditioning and cooling systems by providing improved thermal performance, compactness, and high energy efficiency. New generation microchannel heat exchangers, when installed in chillers, increase efficiency, minimize refrigerant consumption and increase system reliability. This article discusses the most important performance and operational advantages of microchannel heat exchangers in chillers.

How microchannel heat exchangers improve the efficiency of chillers

1. Improved heat transfer characteristics

Microchannel heat exchangers use flat, narrow pipes with multiple parallel channels, which provides a larger heat transfer surface area compared to traditional round pipes. This results in faster and more efficient heat transfer between water or air and the refrigerant. In refrigeration units, this means:

Higher efficiency: More efficient heat transfer reduces the load on the compressor, reducing energy consumptio

Fast cooling response: The smaller size ensures faster temperature stabilization and improved system performance.

2. Reduction of refrigerant consumption

The advantage of microchannel heat exchangers is that they can operate with lower refrigerant consumption. This is especially useful for chillers because:

Lower environmental impact: A smaller volume of refrigerant eliminates leaks and emissions of harmful substances.

Cost-effective advantage: The lower amount of refrigerant required for each system reduces operating and maintenance costs.

3. Reduced weight and dimensions

Microchannel heat exchangers are lighter and more compact than conventional finned-tube heat exchangers. This is especially useful in refrigeration units where space may be limited. The advantages include::

Easy to install: The lower weight reduces the complexity of handling and installation.

Optimal system design: More compact designs ensure better airflow and system integration.

4. Increased durability and corrosion resistance

Microchannel heat exchangers, such as the Trane condenser coil, are usually made of aluminum, which also provides increased corrosion resistance. This allows you to extend the service life of the chiller components in the following ways:

Lower maintenance requirements: Fewer failures due to corrosion means longer maintenance intervals.

Enhanced long-term reliability: The durability of aluminum ensures reliable operation for a long time.

Application in air conditioning and cooling systems

Microchannel heat exchangers are widely used in a wide range of refrigeration applications such as

Air-cooled chillers: More heat dissipation means more cooling efficiency.

Water-cooled chillers: greater heat dissipation reduces pumping energy costs.

Industrial cooling: Higher efficiency allows for large-scale cooling operations with lower energy consumption.

Practical example: Performance of a Trane capacitor coil

One of the best examples of using microchannel technology is the Trane condenser coil, which uses a microchannel design to improve heat dissipation at lower energy consumption levels. Coils offer:

The efficiency is up to 30% higher than that of traditional designs.

A lower pressure drop reduces the energy consumption of the fan and compressor.

Conclusion

Microchannel heat exchangers provide a significant increase in efficiency in refrigeration units and for this reason are the best choice in new cooling and HVAC systems. Improved heat dissipation, reduced refrigerant requirements, and extended service life provide higher costs and environmental benefits. As the industry evolves, products such as the Trane capacitor coil demonstrate the growing importance of microchannel design for maximum performance.

Manufacturers and operators can make their equipment more efficient, cheaper, and more environmentally friendly in terms of cooling by using microchannel heat exchangers.